AlmaCrawler in the IAPAs Shortlist

We are excited to travel to London today to attend the IAPAs – our Billennium SpiderBoom B1890 Quick-Pro has been shortlisted for the IAPA Awards Product of the Year – Self Propelled Booms & Atrium Lifts category.

We’re looking forward to the event tomorrow, 10 March 2022, at the Millennium Gloucester Hotel London Kensington.

We at AlmaCrawler pride ourselves for pushing the boundaries of the status-quo in the aerial platform sector, investing significant resources in research and development with the aim of creating innovation that can simplify and make work safer at high altitudes.

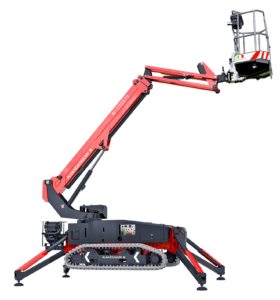

The Billennium line – self-propelled aerial platforms with stabilisers – features two variations for the stabilisation system: VISUAL for products with fixed stabilisation and Quick-Pro for variable area stabilisation. This range of products features two innovative patent-pending systems:

- the first is the AWP system – Adaptive Working Performance – which, thanks to the presence of sensors on the stabilisers, allows the platform to detect the actual position of the machine in real time, automatically adapting its performance;

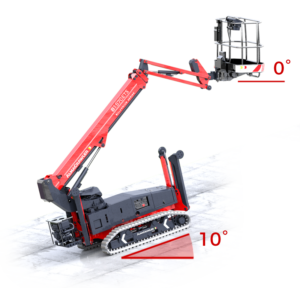

- the second system is called SPS – Self-Propelled skill System – and allows the platform to be used at height without the use of stabilisers, even on longitudinal slopes of up to 10°.

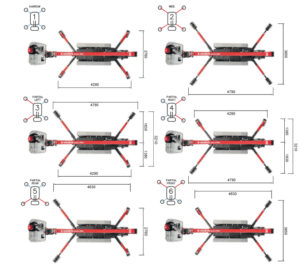

The Billennium B1890 Quick-Pro model differentiates itself by allowing the operator to easily and simply choose between six different configurations, depending on the space available to the operator. With a working height of 18m, a maximum outreach of 10.9m, and most importantly a travel height of 9m – the only stabilized telescopic tracked platform able to travel at height – it is certainly one of our most innovative products.

Officialy launched in April 2021, the Billennium B1890 EVO Quick-Pro has quickly attracted considerable interest from the industry, even winning the Italplatform Innovative Product award in October 2021, an award we at AlmaCrawler took great pride in.

While we impatiently wait for the IAPA Awards that will be held tomorrow, we can only thank all our customers and partners for the incredible support and interest dedicated to us and our products!

- Published in News

PARTECIPAZIONE FIERA MYPLANT & GARDEN 2022!

Iniziativa realizzata nell’ambito dell’ Asse prioritario III – Promuovere la competitività delle piccole e medie imprese.

Azione III.3.b.1.2 – Creazione di occasioni di incontro tra imprenditori italiani ed esteri finalizzati ad attrarre investimenti e a promuovere accordi commerciali e altre iniziative attive di informazione e promozione rivolte a potenziali investitori esteri.

Obiettivo: Svolgere attività di sviluppo e ricerca atte a migliorare la versatilità, semplicità d’utilizzo e sicurezza delle piattaforme aeree.

Il progetto parte con la creazione di una strategia comunicativa per informare clienti, potenziali clienti e fornitori della presenza dell’azienda alla fiera tramite i canali Social e la Newsletter. La partecipazione alla fiera dal 23/02/2022 al 25/02/2022 permetterà all’azienda di sottoporre i prodotti ad un pubblico ampio ed eterogeneo, aumentando di conseguenza la possibilità di trovare nuovi lead interessati alle mini piattaforme aeree cingolate. Saranno presentati ai visitatori dello stand volantini, brochure, gadget nonché i prodotti stessi. Il personale presente accoglierà i clienti, presenterà azienda e prodotti e risponderà alle richieste. Infine, una fase fondamentale sarà quella successiva di follow-up dei contatti, in cui si prevede di sviluppare nuove opportunità di business.

- Published in News, Non categorizzato

AlmaCrawler at Myplant & Garden in Hall 20 stand H50

From 23rd to 25th February 2022 we will take part to the event Myplant & Garden, one of the most important sector shows for the tree nursery, gardening and landscape sector in Italy!

Come and visit us in Hall 20, Stand H50 at the Fiera Milano-Rho exhibition centre to see our new BILLENNIUM 1570 ETS, the JIBBI U-1570 EVO and our tracked scissor lift BIBI 870-BL EVO!

Myplant & Garden is a driving force behind the horticultural and landscape gardening sector in Italy. In addition to encouraging the concept of sustainability and lifestyle, it is the only event where you can see the entire green industry through its 9 macro sectors (nurseries, flowers, decoration, construction, machinery, services, technology, pots, garden furniture). You can read more information and buy tickets from here.

The Spiderboom B1570 ETS combines the main features of self-propelled aerial platforms on wheels with those of stabilised tracked a

erial platforms.

With a max outreach of up to 9.6m, a working height of 15m, our unique fixed area automatic stabilisation system with a width of only 2.48m, and a total weight of 2620kg, the B1570 ETS is a new and morphologically unique product with a simpler user experience and superior market adaptability. In addition, through the revolutionary SPS (Self-Propelled Skilled System) it is possible to use the machine even without lowering the outriggers, on slopes of up to 10° longitudinally, at heights up to max 8m.

The JIBBI U-1570 self-propelled tracked boom lift has a working height of 15.4m, a maximum outreach of 9.65m, and features an ultra-lightweight aluminium boom – the result of our collaboration with Multitel Pagliero. With a total weight of just 2895kg it is transportable and presents an impressively low ground pressure.

The JIBBI U-1570 self-propelled tracked boom lift has a working height of 15.4m, a maximum outreach of 9.65m, and features an ultra-lightweight aluminium boom – the result of our collaboration with Multitel Pagliero. With a total weight of just 2895kg it is transportable and presents an impressively low ground pressure.

Finally, the BIBI 870-BL EVO tracked scissor lift features a 1.5 x 1.20m extendable and foldable basket, a maximum working height of 8m, a basket capacity of 250 kg (two operators) and a travel height of 6m.

Both the BIBI and the JIBBI line feature the automatic patented bi-levelling system that allows them to travel and work on steep slopes or uneven terrain simply and safely, overcoming terrain inclinations up to 25°.

Equipped with endothermic engines, they also feature a 220V or 110V electric pump and can be powered directly from an electrical outlet, which is a fantastic zero-emission solution for indoor and outdoor use.

You will find AlmaCrawler in Hall 20 Stand H50.

- Published in News

AlmaCrawler and GGR Group at the Executive Hire Show

Come see the new ML 3.0 FX at the Executive Hire Show – 9-10 February on stand B12!

One of UK’s most attended trade fairs for the tool, equipment and plant hire industry is back!

We will join our ML Line partners from GGR Group this February for the Executive Hire Show in Coventry at the Coventry Building Society Arena. The Show brings the industry together and is the annual event where hire companies from the UK and Ireland get to meet suppliers and manufacturers, learning about new and innovative solutions. It will be held on Wednesday 9th February & Thursday 10th February 2022, and you can learn more about the show and get your tickets here.

The Multi-Loader product line represented in the UK through our partnership with GGR Group is designed to help you move loads in impossible conditions – do you have large and heavy loads that need to be transported over steep or sloping terrain, or trek through soft and hard terrain on the same jobsite?

The Multi-Loader range will have a solution for you either by using our ML 2.5 or ML 6.0 with the revolutionary patented bi-levelling technology that can overcome slopes of up to 20° or our newly launched ML 3.0 FX that can carry up to 3000 kg, will fit through a door and is fully electric. Read more about this model here and come see it at the Executive Hire Show since it will be featured live in the “Innovation Trail”.

With various power options for the larger models, the new compact tracked carrier ML 3.0 FX is fully electric with two super silent AC motors of 5.3 kW each and equipped with an interchangeable AGM or lithium removable battery pack, an ideal choice for those who have to intensively work in confined spaces, both indoors and outdoors.

GGR Group, founded in 1995 by Graeme and Gill Riley, is the leading UK brand specialising in the sale and hire of lifting equipment. With an excellent sales and technical team, the company has strengthened its presence on an international level.

Want to know more? Visit: https://www.almac-italia.com/ml-line/

- Published in News

Briggs Equipment adds AlmaCrawler’s Jibbi and Bibi line to their fleet

First units of Jibbi 1250 EVO and Bibi 1090 EVO were delivered to Briggs Equipment by Inspectec Access Equipment Sales

The company was acquired by Charles Sammons in 1952 and became a proper independent division of Sammons Enterprises – which is largely a financial and insurance group – in 1996, when it also dropped the Weaver name, becoming Briggs Equipment. That same year it opened its first overseas operation in Mexico, where it was appointed the Yale forklift dealer.

In 2006 it moved into the UK when it acquired the material handling division of Caterpillar dealer Finning UK which said at the time that it wanted to focus its efforts on its Hewden rental business.

- Published in News

CPL becomes AlmaCrawler’s UK distributor for AWP Line

AlmaCrawler has signed an exclusive distribution agreement with Cumberland Platforms Ltd for its AWP product line for the entire UK territory.

Established in 2011 by Paul and Michela Murphy, CPL Ltd quickly became one of the leading players in the UK access industry with one of the widest product ranges in the country.

The company’s highly skilled team offers sales of and technical service for lifting platforms throughout the UK, offering customers a simple and straightforward user experience. Quality excellence has always been one of the company’s main objectives: CPL has achieved numerous quality certifications, including: ISO 9001, HEA (Highways Electrical Association), IPAF and VCA.

Commenting on the new partnership, CPL’s Managing Director Paul Murphy, said the following: “We have seen incredible growth in CPL over the past few years and to help with this continual success I wanted a quality product that could be sold and maintained by us without impacting our production. I was impressed with the Almac product and its quality. Once I visited the factory and met the Almac team my mind was made up, Almac is a perfect fit in the CPL portfolio and I’m really excited for 2022 and beyond‘’.

Our General Manager, Andrea Artoni, said: “We are delighted to partner with CPL for our AWP Line products in the UK. Through this partnership we will consolidate our presence throughout the UK, strengthening our sales and support service for the Bibi, Jibbi and Billennium products that our customers have come to appreciate. We strongly believe this new partnership with the CPL team will create great results since we share core values and operate with the same professionalism and determination.”

AlmaCrawler and Cumberland Platforms Ltd signed the agreement following visits to both HQs, both confident that the partnership will be able to offer UK customers a higher standard of service.

Since launching its first self-levelling scissors in 2013, AlmaCrawler has been steadily expanding, determined to consolidate its market in the UK.

- Published in News

Almacrawler partners with Vannucci Piante to supply its unique aerial platforms

The Italian industry giant Vannucci Piante chooses the BIBI and JIBBI lines

Vannucci Piante is one of the undisputed global leaders in the tree nursery industry. Based in Tuscany Italy, it grows and exports more than 3000 plant varieties in more than 60 countries around the world, including Buckingham Palace!

Almacrawler Italia partnered with Vannucci Piante to match them with one of our unique aerial platforms for their Pistoia (Tuscany) HQs in order to:

- improve safety standards

- facilitate daily operations

- perfectly cater to the operator needs of the tree nursery sector giant.

After a visit at the Almacrawler Viadana premises, Vannucci Piante’s Purchasing Team identified both the BIBI and JIBBI lines as adequate and able to handle the range of applications the tree nursery company has to handle.

Almacrawler delivered the BIBI 870 EVO and JIBBI 1250 EVO at the beginning of May and provided a two-day training with on-site operators, exploring all the various capabilities the two models allow for.

Watch the video below that features the highlights of those two days of training.

- Published in News

MULTI AWP is the official distributor for AlmaCrawler in Poland

AlmaCrawler teams up with MULTI AWP for the AWP and Material Handling Product Lines in Poland.

AlmaCrawler, Italian self-levelling crawler lifts manufacturer, has signed an agreement with MULTI AWP who becomes the official dealer for the AWP and Material Handling Lines in Poland.

Newly established, MULTI AWP is headed by Lucjan Bogdan, an industry veteran in the country with 14+ years of experience in building brand recognition for well-known lift manufacturers. The wealth of knowledge in selecting the right equipment has allowed the company to quickly establish itself and adequately support rental companies and end users alike.

MULTI AWP will work closely with its two supporting partners – Spiderlift (company specializing in renting, selling and servicing Pajak crawler unit lifts) and Małe Żurawie (rental company with a growing mini crane rental fleet supplying for installation of structures, oversized glass, relocation of machinery and confined space applications).

Commenting on the new partnership, Lucjan Bogdan said the following: “Through this collaboration MULTI AWP and AlmaCrawler will build a stronger presence in Poland. We were quite literally fascinated by the driving properties of these machines. The patented and unique bi-leveling system will allow our customers to solve a lot of problems on site. The possibility to work on important gradients is the unique functionality of these machines, which coupled with the high quality of the AlmaCrawler products and support will be key to its success here in Poland.”

AlmaCrawler Dealer Network Manager, Jonathan Vioni, said: “We are extremely pleased to have established a new official partnership in a rapidly growing market like Poland that is experiencing an increasing demand for problem solving and superiorly safer products. In order to cater to that increasing demand our goal was to reinforce our presence in the country through a strategic partnership with market-aware, experienced, business-savvy partners. This is why we were pleased to define this agreement with MULTI AWP and partner companies Spiderlift and Male Zurawie managed by Mr Lucjan Bogdan and Piotr Niewiarowski, and therefore be able to offer a full coverage for sales and dedicated service all around Poland, for both our AWP Line (BIBI, JIBBI and Billennium machines) as well as the Material Handling Line – the Multi-Loader range.”

Following a series of both virtual and live negotiations, AlmaCrawler and MULTI AWP have reached an agreement, both confident that the partnership will be able to offer the Polish market a higher standard of services.

AlmaCrawler has been constantly growing since it rolled out its first self-levelling scissor lift in 2013, and with more than 35 dealers worldwide, it continues to expand its dealer network while increasing its product lines.

- Published in News

AlmaCrawler & GISEXPO 2021 a show to remember

AlmaCrawler wins the Italplatform Product Innovation Award at GISEXPO 2021!

The GIS EXPO 2021 finished on the 9th October, the biannual show that we always participate with immense enthusiasm. Being able to see partners, collaborators and clients for the first time face-to-face in a very long time was both emotional and exciting. We can 100% say that the show was a success, furthermore during the second day, the Italplatform 2021 Awards Ceremony was held we at Almacrawler…

Won the Product Innovation Prize!

Our new Billennium B1890 EVO Quick-Pro won the Product Innovation Prize! Our tracked stabilized boom lift features multiple technologically new characteristics but the AWP (Adaptive Working Performance) system that allows for real time reading of the angle of descent and positioning of each stabilizers and hence an accuracy in determining the stabilized area like never before, and also the SPS (Self-Propelled System) which allows our platform to work at height without lowering the stabilizers. These and the other unique features of the Billennium line convinced the panel of judges to assign it this prestigious award!

Thank you!

We’d like to think all the GIS EXPO 2021 visitors: it was great to see a lot of you in person for the first time, and to see and catch up with old clients and friends.

A big thank you goes to the organizers of the show for a well coordinated event and we also want to thank Italplatform panel of judges for believing in us and our product.

Finally we’d like to thank our incredible AlmaCrawler team without which we would’ve never been able to win this prestigious award or had such a successful show! It is our combined courage, creativity and sheer will that gets us the amazing results!

Watch our GIS EXPO video here

We had a great time at the show and you can see the highlights of our time there in our new video!

- Published in News

GGR Group becomes the UK Multi-Loader Line exclusive distributor for AlmaCrawler

AlmaCrawler teams up with GGR Group for the Material Handling Multi-Loader Line in the UK

AlmaCrawler has signed a distribution agreement with GGR Group for the Multi-Loader Line for the whole territory of the UK.

Established in 1995, GGR Group is the Number 1 brand for lifting solutions. The company was founded by Graeme and Gill Riley and offers sales and hire of specialist lifting equipment throughout the UK, supported with an expert technical team, a service department, and accredited training centres nationwide.

Commenting on the new partnership, CEO for GGR Group, Graeme Riley said the following: “Through this collaboration GGR and AlmaCrawler will continue to support the UK construction industry to hit is environmental targets and eventual zero carbon emissions. The partnership will deliver products that are safer, more efficient, ergonomic, electric, fabricated to the highest standards supported by excellent after sales service making the UK a greener place.”

AlmaCrawler general manager, Andrea Artoni, said: “We are delighted to be partnering with GGR Group for our Multi-Loader Line products in the UK. This will strengthen our presence, first and foremost benefiting our longstanding and new clients because they will be able to rely on expert, professional advice and support. We have worked with this company in the last few years with excellent results and are very much looking forward to continue this collaboration.”

Following a series of virtual negotiations, AlmaCrawler and GGR Group have officially signed the agreement last week at Vertikal Days, both confident that the partnership will be able to offer British customers a higher standard of services.

AlmaCrawler has been constantly growing since it rolled out its first self-levelling scissor lift in 2013, and with more than 35 dealers worldwide. Following the establishment of their UK subsidiary – Almac Atlantic LTD, the Italian company has confirmed a series of partnerships with UK key players and expects to continue consolidating its British market and improve overall market share.

- Published in News

Italiano

Italiano Deutsch

Deutsch Español

Español Français

Français