Codici brevetti – patent codes

Nos brevets

EU Patent N. EP3177561 B1

US Patent N. US10399834B2

AU Patent N. AU2015298492 B2

CA Patent N. CA2955645 C

RU Patent N. RU2711828 C2

- Publié dans Non categorizzato

AlmaCrawler in the IAPAs Shortlist 2024

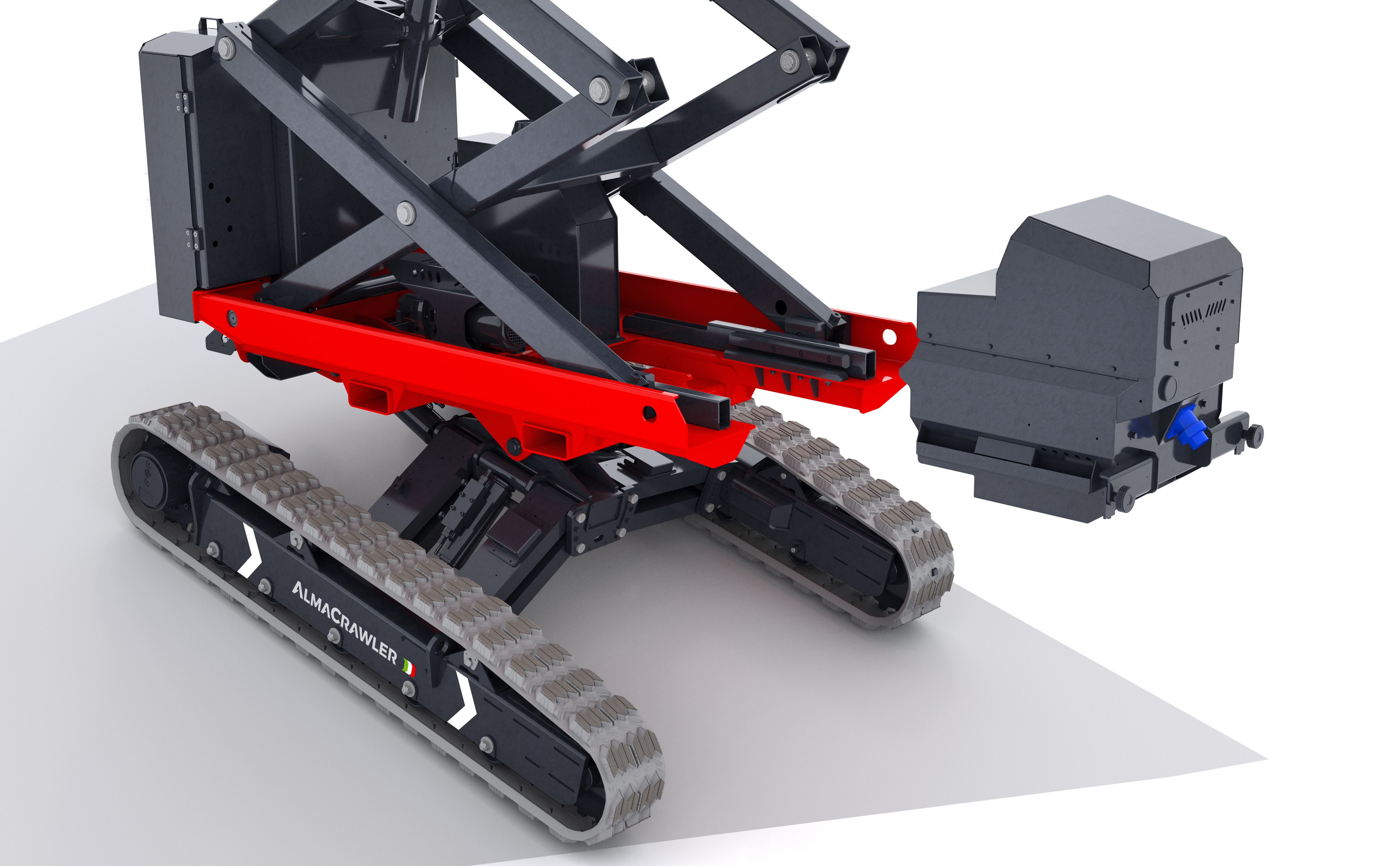

We are excited to travel to Denmark on 13 March 2024 to attend the IAPAs– our BIBI 1090 PRiMO been shortlisted for the IAPA Awards Product of the Year – Scissor Lifts & Vertical Masts category.

The event will be held at the Scandic Copenhagen Hotel, in Copenhagen, Denmark, and we look forward to attending!

AlmaCrawler’s commitment is to push the boundaries of the aerial work platform industry by investing significant resources in researching and developing new technologies that simplify and improve the safety of operators when working at height.

The BIBI 1090 PRiMO represents our past and our future – a return to the platform with which we started, designing it in a current key, a highly desired and very important update.

The BIBI 1090 PRIMO is a fully electric aerial platform with electric drive, in line with the other products in the PRiMO line. It has a fully removable battery pack to allow the platform greater flexibility of use than other full-electric offerings currently on the market.

Why removable? Our answer is simple: Why not?

The BIBI 1090 PRiMO appeals both to rental companies looking to electrify their fleets, and to all those who are aware of new sustainability regulations and the use of alternative energy sources.

The development of the BIBI 1090 PRiMO was mainly motivated by a growing demand for electric aerial platforms, also for outdoor use. Concern for a less polluted future, customer feedback and developments in electric drive technology played a significant role in the design of this new platform.

Here are some of the main benefits and advantages of the BIBI 1090 PRiMO:

- Electric drive – allows a maximum speed of 4.5 km/h.

Removable battery pack for extended use and easy charging, zero emissions and noise pollution.

Removable battery pack for extended use and easy charging, zero emissions and noise pollution.- Updated design for greater functionality and a better user experience.

- Suitable for use on construction sites with limited access to power sources, thanks to the ability to remove and replace the battery pack on the job site.

- EAS Anti Entrapment System, technology designed to prevent serious injury by stopping the unit but allowing space for the operator to safely remove himself.

- Automatic Track Tensioning System – ZERO maintenance

Our long-term goals for the BIBI 1090 PRiMO are ambitious. We aim to significantly expand its presence and consider introducing complementary products and services that can further improve performance and safety, as well as more comprehensively meet the changing needs of our customers.

Our mission is to be at the forefront of offering sustainable solutions for work-at-height and material handling equipment, and we are constantly striving to achieve this goal.

- Publié dans News

AlmaCrawler signe un nouveau partenariat en France avec NACELEXPERT pour sa gamme de Nacelles élévatrices.

AlmaCrawler, l’un des principaux fournisseurs de Nacelles élévatrices, a le plaisir d’annoncer la signature officielle d’un accord de distribution avec Nacelexpert pour la distribution exclusive de ses gammes AWP sur le territoire français.

Fondée en 2006 par Frédéric Allier et Thierry Brun, Nacelexpert s’est rapidement imposée comme un acteur de premier plan dans le secteur. La société dispose d’une équipe dévouée et hautement qualifiée qui supervisera les opérations de vente et de service de la famille de produits AWP de AlmaCrawler. Cette gamme complète comprend des lignes de produits renommées telles que BIBI, JIBBI et Billennium, et s’engage à soutenir d’éventuels développements futurs.

Frédéric Allier, Gérant de Nacelexpert, s’est exprimé sur ce nouveau partenariat : « Nous recherchions un nouveau partenariat significatif avec un constructeur innovant. Cet accord stratégique avec AlmaCrawler nous permettra d’apporter des solutions d’élévation spécifiques pour les chantiers très exigeants. Nous sommes confiants dans l’expérience et le niveau technique des équipes d’AlmaCrawler. Ce contrat de distribution exclusif s’inscrit dans une dynamique d’innovation et de différenciation qui est la raison d’être de NacelExpert. »

Jonathan Vioni, directeur du réseau de concessionnaires AlmaCrawler, a souligné l’importance stratégique de cette collaboration en déclarant : “La France représente une pierre angulaire pour la croissance future d’AlmaCrawler. Nous sommes ravis d’avoir formalisé cet accord avec Nacelexpert, un acteur clé et respecté sur le territoire français. Grâce à nos activités commerciales florissantes avec le clients « Tier 1 » et à notre riche histoire sur l’un des plus grands marchés européens, cette collaboration marque une étape cruciale. Elle nous permet d’étendre notre présence dans l’industrie de la location, de renforcer nos liens avec les clients existants et de capitaliser sur l’énorme potentiel de ce marché”.

Vioni a ajouté : “Nos gammes de produits innovants et polyvalents, associés à l’accent mis sur la technologie et l’innovation, s’harmonisent parfaitement avec la crédibilité, la structure organisationnelle, l’histoire du marché et l’expérience de Nacelexpert. Ce partenariat nous permet de mettre en œuvre ce projet avec toute la force nécessaire et de fournir des solutions optimales au marché”

L’accord entre AlmaCrawler et Nacelexpert est le résultat d’une série de réunions exploratoires, témoignant de la confiance mutuelle dans le développement des activités des deux partenaires en France.

AlmaCrawler connaît une croissance constante depuis l’introduction de sa première plate-forme à ciseaux autonivelante en 2013. Le constructeur a développé un réseau mondial de plus de 40 concessionnaires à ce jour. L’entreprise reste déterminée à poursuivre sa croissance en diversifiant ses gammes de produits, en pénétrant de nouveaux segments de marché et de nouvelles industries.

Pour plus d’informations, veuillez contacter : marketing@almac-italia.com

- Publié dans News

AlmaCrawler forges dynamic partnership with TRANSGRUAS for Material Handling Line in Spain

AlmaCrawler, a leading innovator in the material handling industry, has officially signed a distribution agreement with TRANSGRUAS, effectively enhancing its presence in the Spanish market. This strategic collaboration promises to positively impact both companies work in the Spanish market of material handling products.

With a rich history spanning over four and a half decades, TRANSGRUAS has firmly established itself as a major player in the crane and mini crane business in Spain. The company’s expansive reach extends across the entire Spanish market, making them a respected and recognized name in the industry.

In response to this exciting partnership, TRANSGRUAS expressed its conviction that the combination of AlmaCrawler’s cutting-edge and innovative equipment and TRANSGRUAS‘ 45 years of invaluable experience in the lifting sector will yield resoundingly positive outcomes for all stakeholders involved. This sentiment underscores the optimistic outlook that this collaboration brings to the table.

Karim Sinno, AlmaCrawler’s Sales Manager for Material Handling, expressed his enthusiasm for the partnership, saying, “We are extremely pleased and proud to have established a new official partnership for our Material handling line with a great company like TRANSGRUAS. We see, in this new business collaboration, a great opportunity for both TRANSGRUAS and AlmaCrawler to do very good business in the Spanish market.”

This partnership signifies a positive step forward for both AlmaCrawler and TRANSGRUAS, with the potential to reshape the material handling landscape in Spain. The collaborative spirit and dedication to excellence shared by these two industry leaders promise a bright and prosperous future, setting the stage for groundbreaking developments in the Spanish market.

For further info, please contact marketing@almac-italia.com

- Publié dans News

AlmaCrawler celebrates its 10th anniversary: A week to remember

Thank you everyone for a truly unforgettable week!

Over the past 10 years, we’ve accomplished the seemingly impossible, and it’s all thanks to you – our valued partners, loyal customers, talented distributors, and our exceptional employees.

You’ve placed your trust in us, our visionary ideas, and our boundless creativity.

To mark our remarkable 10th anniversary, we unveiled our new version of our valued scissor lift on crawler – the BIBI 1090 PRiMO, the first BIBI with a full electric drive, powered by a fully removable and interchangeable battery pack!

The BIBI 1090 PRiMO has also been equipped with important new features including the AES Anti-Entrapment System and the ATS Automatic Tensioning System.

Our Jibbi 1890 PRiMO also took home the award for best product above 6mt at the GIS EXPO 2023 (shared with another great product).

This fills us with immense pride, satisfaction, and overwhelming emotion!

We extend our heartfelt gratitude to all of you and to our remarkable team who made this journey possible.

They’ve never shied away from tackling the impossible because that’s what we do best…

We design the impossible.

- Publié dans News

AlmaCrawler launches the ML 1.5 FX – mini crawler transporter

Introducing the ML 1.5 FX: The Compact Tracked Transporter Revolutionizing Material Handling

AlmaCrawler, a leading innovator in AWP manufacturing and more recently material handling solutions, is thrilled to unveil its latest breakthrough product, the ML 1.5 FX, at the APEX 2023 show in Maastricht, the Netherlands, on June 6th. This fully electric tracked transporter is set to revolutionize the way industries handle materials, providing exceptional performance and efficiency, following suit with the Italian companies other Multi-Loader range products.

AlmaCrawler has a strong reputation for pioneering cutting-edge access equipment and material handling solutions that cater to the evolving needs of various industries. With a relentless commitment to pushing boundaries and embracing technological advancements, the company has consistently delivered exceptional products that empower businesses worldwide.

Designed with precision and versatility in mind, the ML 1.5 FX is specifically tailored for crane rental companies, industrial material handling, routine and extraordinary maintenance operations, and the glass and glazing sector. With its compact size and impressive transport capacity of up to 1500kg, the ML 1.5 FX offers unprecedented versatility. It enables seamless movement and precise positioning of heavy loads, enhancing operational efficiency across various industries. This innovative solution empowers operators to navigate tight spaces and maneuver effortlessly, maximizing productivity while reducing downtime.

One of the ML 1.5 FX‘s standout features is its fully electric drive system, setting new standards in sustainability and operational excellence. Equipped with two powerful electric motors generating a robust 10.6kW of power, the ML 1.5 FX ensures immediate traction and accelerates to a maximum speed of 2.8km/h. The two-speed functionality allows operators to choose between optimal speed and power, depending on the task at hand.

By eliminating the need for hydraulic oil, this design minimizes environmental impact while enhancing safety and reliability.

The electric drive system delivers exceptional performance while eliminating the need for hydraulic oil. This design feature not only makes the ML 1.5 FX IP67 rated, but also enhances operational and environmental safety.

Powered by 55Ah AGM batteries, the ML 1.5 FX boasts remarkable efficiency. With a charging time of just 6 hours, the batteries provide uninterrupted operation, eliminating the need for maintenance. Additionally, the transporter’s ground clearance of 4cm and a gradeability of 45° ensure seamless navigation across various terrains.

“AlmaCrawler is proud to introduce the ML 1.5 FX, a game-changing solution that will redefine how industries handle materials,” said Karim Sinno, the new Material Handling Distribution Manager at AlmaCrawler. “We have incorporated cutting-edge technology and user-centric design to deliver a tracked transporter that exceeds expectations in terms of performance, efficiency, and sustainability. This innovation represents our unwavering commitment to empowering businesses with state-of-the-art material handling solutions.”

The ML 1.5 FX stands out from its competitors not only due to its compact size and impressive transport capacity but also for its suitability to independent operators. Its versatility makes it ideal for a range of applications, including industrial operations, maintenance work, glazing industry, and even the food and pharmaceutical sectors, thanks to its IP67 rating.

AlmaCrawler invites all attendees of the APEX 2023 show in Maastricht, the Netherlands, to experience firsthand the unparalleled performance and groundbreaking features of this innovative tracked transporter – alongside the rest of the Multi-Loader range on the 6-8th June!

- Publié dans News

AlmaCrawler grows its sales team

AlmaCrawler welcomes Karim Sinno as new Material Handling Equipment Sales Manager.

Karim Sinno joins AlmaCrawler after 6 years as Export Area Sales Manager at MultiOne, the Italian manufacturer of multifunctional loaders. Karim will be using his sector know-how and experience with agri and construction equipment to further increase the commercial success of AlmaCrawler’s material handling range.

Sinno joins AlmaCrawler’s sales team and will be directly responsible for the Multi-Loader and T-Crane lines, working with the company’s established network of distributors as well as further developing it.

Andrea Artoni, CEO of AlmaCrawler said: “Our team is and will be growing exponentially in the next few years, and the arrival of Karim Sinno in our sales team represents a great opportunity to further strengthen our work with our distribution network. The last couple of years have confirmed an increasing interest in our innovative Material Handling products and we look forward to a positive global expansion.”

Karim says about joining AlmaCrawler: “I’m really looking forward to fully taking advantage of this new professional opportunity and work towards developing the market of these innovative products further. And I feel like I’m joining a real work family so I’m excited about what the future will bring for us.”

For further info, please contact marketing@almac-italia.com

- Publié dans News

AlmaCrawler in the IAPAs Shortlist 2023

We are excited to travel to London on 19 April 2023 to attend the IAPAs– our JIBBI 1890 PRiMO been shortlisted for the IAPA Awards Product of the Year – Self Propelled Booms & Atrium Lifts category.

The event will be held at the Millennium Gloucester Hotel London Kensington and we look forward to attending!

AlmaCrawler’s commitment is to push the boundaries of the aerial work platform industry by investing significant resources in researching and developing new technologies that simplify and improve the safety of operators when working at height. JIBBI 1890 PRiMO is an integral part of the JT series which it extends, featuring the same innovative levelling technology that sets the AlmaCrawler products apart, self-levelling on slopes up to 15° laterally and longitudinally.

The JIBBI 1890 PRiMO is a full electric with electric drive 18m working height tracked telescopic boom – self-propelled up to 14m even on slopes, a unique feature.

With a total weight of 5900 kg, it is the lightest 18 m telescopic boom, capable of operating even on heavy, sloping and slippery terrain. With a 250kg basket capacity, it features two options for the operating reach – max 9.9m in the 140kg working diagram and max 8.3m in the 250kg working diagram.

The PRiMO features a fixed track width of 2.20m that will comfortably allow it to work in narrow spaces and self-tensioning tracks. This makes the PRiMO maintenance free so no more grease!

The length of the tracks and width of the tracks also ensure superior grip but create low ground pressure, and with a 38cm ground clearance, will make working on rough, rocky or muddy terrain, easier than ever.

As the previous models of the same family, the JIBBI 1890 PRiMO uses the automatic levelling system “Dynamic Levelling”, developed to compensate gradients of up to 22° (40%) during transport operations, and the Pro-Active Levelling technology, which intervenes automatically during “driving at height” operations.

The JIBBI 1890 PRiMO is the first fully electric with electric traction AWP launch for AlmaCrawler – the PRiMO has three battery pack options which are COMPLETELY REMOVABLE and REPLACEABLE – meaning that you can potentially achieve infinite autonomy and allow the platform to work non-stop by simply changing its battery pack as you would do with an electric tool.

The JIBBI 1890 PRiMO is the first fully electric with electric traction AWP launch for AlmaCrawler – the PRiMO has three battery pack options which are COMPLETELY REMOVABLE and REPLACEABLE – meaning that you can potentially achieve infinite autonomy and allow the platform to work non-stop by simply changing its battery pack as you would do with an electric tool.

The options are:

- ELC – Lead Acid 420Ah 48V – 720kg – 6.5h recharge time

- LTH 330 – Lithium 330Ah 48V – 300kg – 5h recharge time

- LTH 440 – Lithium 440Ah 48V – 350kg – 6.5h recharge time

As a standard, it features a 1.8 m wide basket which rotates +/- 70° guaranteeing a maximum capacity of 250 kg. The controller has been redesigned to streamline the operator’s user experience and features a standard anti-entrapment system that helps to protect the operator against crushing accidents.

The AES anti-entrapment system is designed to prevent serious injury by stopping the unit when the operator is crushed against it. Our innovative system furthermore will go back on its trajectory for 3-5 seconds allowing space for the operator to safely remove himself.

Like all the AlmaCrawler products, the JIBBI 1890 PRiMO is equipped with high-standard technology that enhances its performance mix, combining “Weight, Dimensions, Working Height and Operating Reach”. Here are the extras that the JIBBI 1890 PRiMO can be equipped with:

Like all the AlmaCrawler products, the JIBBI 1890 PRiMO is equipped with high-standard technology that enhances its performance mix, combining “Weight, Dimensions, Working Height and Operating Reach”. Here are the extras that the JIBBI 1890 PRiMO can be equipped with:

- Ultrasonic anti-collision system, to protect operators in the basket with anti-crush barrier function in the two directions of movement of the basket (in the upper and lower part). This system protects operators from unforeseen and accidental impacts.

- New work lights as a helpful tool both for nighttime work as well as job sites with limited visibility.

The JIBBI 1890 PRiMO was launched at the Bauma 2023 trade fair and has already proven to be a big hit with visitors, customers, and partners. It represents the evolution of our JT-LINE telescopic boom platform product range, taking work at heights to the next level.

- Publié dans News

Matelev nouveau distributeur de la ligne Multi-Loader et T-Crane de AlmaCrawler en France

AlmaCrawler a signé un accord de distribution officiel pour la France avec MATELEV par sa ligne de produits « Material Handling ».

Fondée en 2016 par Frédéric Leclerc, MATELEV est rapidement devenue l’un des principaux acteurs dans le secteur des grues et des mini-grues, avec une vaste gamme de clients dans différents secteurs et industries, ainsi que dans le secteur de la location.

L’équipe dévouée et hautement qualifiée de la société offre un service ventes et technique avec une expérience utilisateur simple et directe, avec une forte orientation vers le produit.

Frédéric Leclerc, directeur général de Matelev, a déclaré ce qui suit à propos de ce nouveau partenariat : « Nous sommes très heureux de ce nouveau partenariat et nous remercions Almacrawler pour la confiance accordée. Avec un marché en pleine croissance et une demande de plus en plus forte, ce nouveau partenariat élargi la gamme de matériel proposée par Matelev et permet de répondre mieux à nos clients pour les problèmes de transport de charges lourdes sur sol industriel ou tout-terrain. Matelev commercialise et assure le service après-vente des Multi-Loader et T-Crane sur tout l’hexagone. En plus un nouveau show-room est disponible à Saint-Fargeau-Ponthierry (77) où une équipe technique attend les clients par répondre à tous questions et visionner les nouveaux produits de Almac ».

Le responsable de le réseaux Distributeur de AlmaCrawler, Jonathan Vioni, a déclaré : « Nous sommes extrêmement heureux d’avoir établi un nouveau partenariat officiel pour notre gamme Multi-Loader et T-Crane. La demande croissante de produits polyvalents et “problem solving” pour compléter et satisfaire les besoins quotidiens du client dans les activités de manutention et entretien, correspond parfaitement à la proposition de notre gamme. La France est un excellent marché pour nos produits Multiloader depuis que nous les avons introduits il y a deux ans et demi. Il était donc temps d’établir une présence plus dédiée et un réseau plus étendu, une présence délibérément axée sur le rapprochement entre AlmaCrawler et nos clients et leurs besoins quotidiens spécialisés. Nous sommes très enthousiastes à l’idée d’entamer ce nouveau partenariat avec Matelev, qui permettra d’améliorer les ventes et le service après-vente dans tout l'”Hexagone” ».

Après des réunions exploratoires, AlmaCrawler et Matelev ont signé ce nouvel accord, tous deux confiants dans leur capacité de porter la gamme de produits Multi-Loader et T-Crane à un niveau supérieur.

Après des réunions exploratoires, AlmaCrawler et Matelev ont signé ce nouvel accord, tous deux confiants dans leur capacité de porter la gamme de produits Multi-Loader et T-Crane à un niveau supérieur.

AlmaCrawler n’a cessé de croître depuis qu’elle a déployé son premier élévateur à ciseaux à nivellement automatique en 2013, et avec plus de 40 concessionnaires dans le monde entier, elle continue d’étendre son réseau de concessionnaires tout en augmentant ses lignes de produits.

- Publié dans News

JIBBI 1890 PRiMO launched at Bauma 2022

AlmaCrawler officially launched the new JIBBI 1890 PRiMO at bauma 2022, a new full electric product for its line of self-levelling telescopic boom platforms.

The new JIBBI 1890 PRiMO is the first 18m working-height product in the JIBBI Line, fully electric and with electric drive.

Equipped with our unique patented automatic bi-leveling system that allows it to work and travel on slopes up to 22°, the JIBBI 1890 PRiMO is self-propelled up to 14m and allows the operator to safely work in a wide range of job site conditions without sacrificing efficiency. With a 10m outreach and a maximum basket capacity of 250kg, it features a number of industry-demanded new features, including:

- Fully removable power pack designed to ensure infinite autonomy and be easily transported for off-site charging. With a choice between interchangeable Lead Acid or Lithium power packs, and two critical options for recharging: the standard 110/220 VAC input or via the industry-first EV Type 2 input, the PRiMO is designed for flexibility.

- Completely reimagined controller for a streamlined user experience based on industry-accepted standards and rental sector needs. Two USB recharging stations available on each controller.

- Anti-Entrapment System as a standard feature – a safety system designed to prevent serious injury by stopping the unit but allowing space for the operator to safely remove himself.

- Electric Drive – the fully electric JIBBI 1890 PRiMO can be driven at a max speed of 4.5 km/h thanks to its electric drive, essentially bridging the gap between standard flat surface mobility and tracked machinery.

- Automatic Tensioner System – is the first JIBBI in the range to feature our automatic track tensioner system, the technology that creates ZERO MAINTENANCE for the tracks.

The available extras were designed to enhance the operator visibility and safety on the job site:

- Ultrasonic Anti-Collision System, which not only monitors the area above and below the basket by preventing collisions with obstacles during aerial operations, but can also detect the presence of possible potholes or unevenness of the ground during movement at height.

- New work lights as a helpful tool both for nighttime work as well as job sites with limited visibility.

Watch the presentation of the JIBBI 1890 PRiMO here:

- Publié dans News

English

English Italiano

Italiano Deutsch

Deutsch Español

Español